Our Services

Established in 1965, Tabor specializes in precision sheet metal processing, with core expertise in laser cutting and stamping. In addition, we perform small-scale manual welding, manual drilling, and finishing operations to ensure the quality and accuracy of final parts.

Laser Cutting

We provide laser cutting services for steel plates up to 12 mm thick, stainless steel plates up to 8 mm thick, and aluminium up to 6 mm thick, with maximum dimensions of 3000 mm x 1500 mm. Cutting operations are carried out using advanced nitrogen laser systems or CO₂ technology.

Our equipment is designed to perform high-precision cuts while minimizing thermal deformation, ensuring superior quality and accuracy in the finished components.

CNC Bending Press

We provide precision bending services for steel and aluminium plates with very low tolerances.

Our equipment is capable of bending plates up to 3000 mm in length and 5 mm in thickness, with the possibility of handling thicknesses of at least 8 mm depending on part geometry.

In addition, we offer automated sheet metal bending for widths up to 2100 mm and capacities of up to 100 tons, ensuring accuracy, consistency, and efficiency in production.

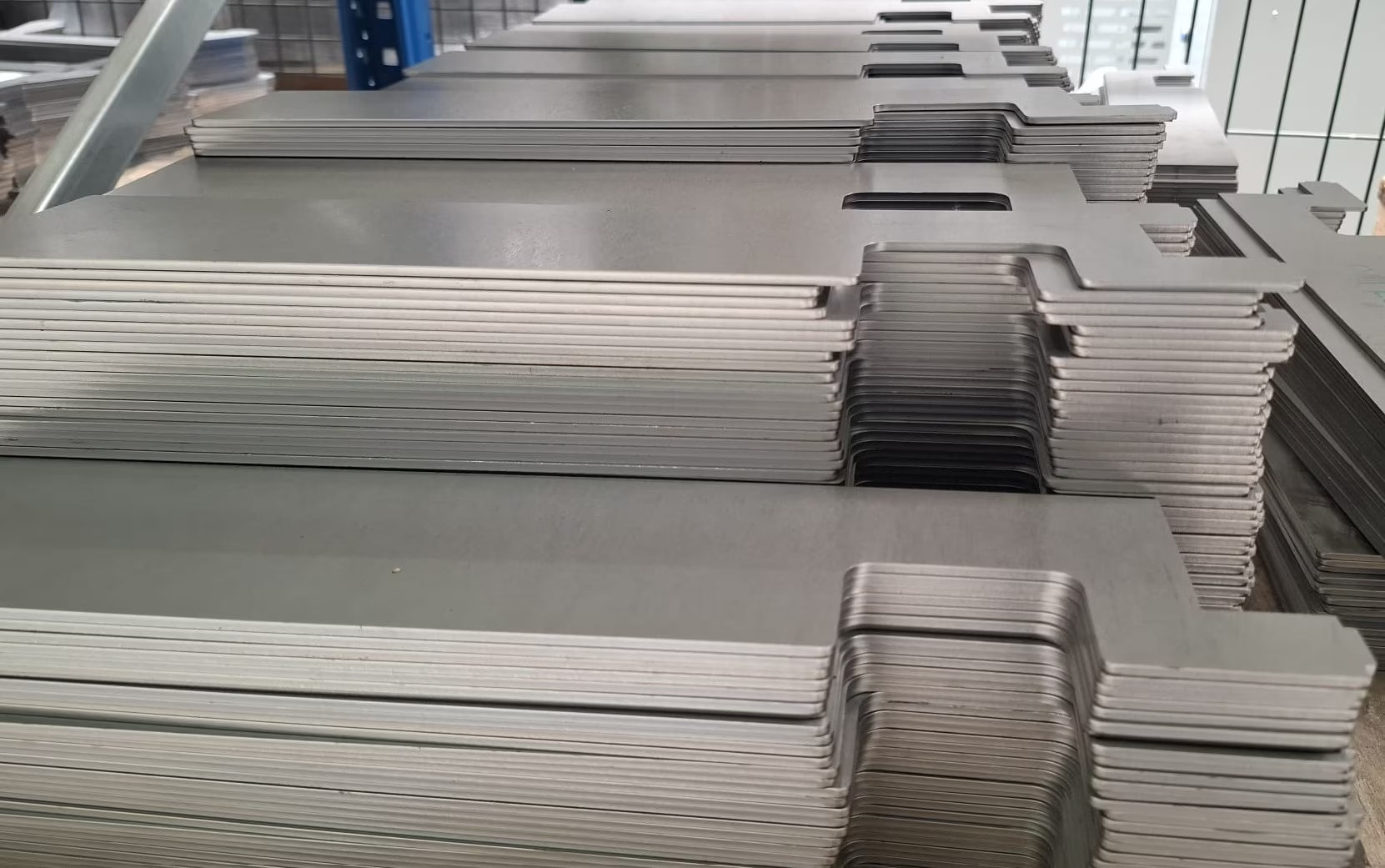

Stamping Systems

Sheet metal stamping represents one of Tabor’s core technological capabilities, supported by continuous investment and extensive expertise in the field.

The maximum capacity of our stamping presses is 315 tons in mechanical presses or 160 tons in hydraulic presses.